Thern Winches and Cranes

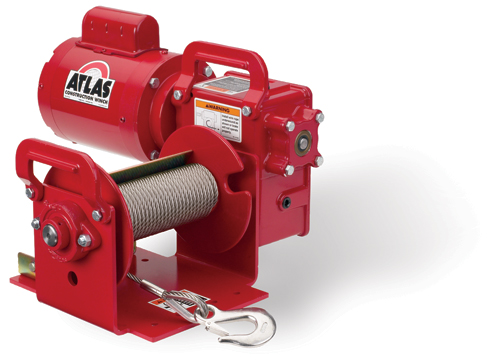

Thern winches and cranes have established a world-wide reputation for toughness, versatility and reliability. Our ability to provide clients with a full range of services, and custom-built solutions has made us a leader among our peers. Whether you need to lift, pull, tension or position, from 100 lbs. to 100,000 lbs., Thern has the perfect product for you.

Superior quality is designed into every product we manufacture. Any manufacturer can say they build a better crane or winch. Thern can back that claim up with a steadfast reputation for dependable products chosen time and again by companies worldwide. Thern products are manufactured to high quality standards because your application is our application. We also understand that some jobs require a tool that isn’t available right off the shelf. That’s why Thern employs an experienced engineering and technical sales staff that can consult, design and manufacture custom products to provide the best possible solution for your application.

Every product we manufacture must meet our strict quality standards or it doesn’t carry the Thern name. Our quality management system is certified to ISO 9001/2008. All new products are rigorously tested to ensure performance and durability. Thern has the ability to test products statically and dynamically with load capacities up to 55,000 lb and line speeds of up to 200 fpm. Test and inspection certificates are available upon request.

Since 1948, Thern has been serving a broad range of industries all over the world. Some key industries served by our products include: Water/Wastewater, Entertainment, Oil and Gas, Bulk Handling, Government/Defense, Mining, Construction, Manufacturing and Marine.

Superior quality is designed into every product we manufacture. Any manufacturer can say they build a better crane or winch. Thern can back that claim up with a steadfast reputation for dependable products chosen time and again by companies worldwide. Thern products are manufactured to high quality standards because your application is our application. We also understand that some jobs require a tool that isn’t available right off the shelf. That’s why Thern employs an experienced engineering and technical sales staff that can consult, design and manufacture custom products to provide the best possible solution for your application.

Every product we manufacture must meet our strict quality standards or it doesn’t carry the Thern name. Our quality management system is certified to ISO 9001/2008. All new products are rigorously tested to ensure performance and durability. Thern has the ability to test products statically and dynamically with load capacities up to 55,000 lb and line speeds of up to 200 fpm. Test and inspection certificates are available upon request.

Since 1948, Thern has been serving a broad range of industries all over the world. Some key industries served by our products include: Water/Wastewater, Entertainment, Oil and Gas, Bulk Handling, Government/Defense, Mining, Construction, Manufacturing and Marine.